How to Fix Refrigerant Leaks in Workshop AC Units

When Workshop AC Units Stop Cooling Efficiently

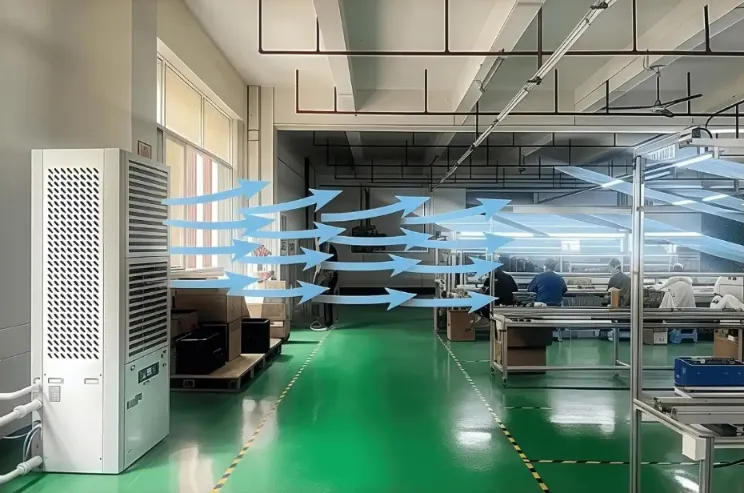

Workshop environments get hot and dusty fast. Industrial air conditioner units keep things bearable during long shifts. But problems crop up. Reduced cooling hits hard. Power bills climb. Refrigerant leaks often cause this mess.

This article dives into spotting and fixing those leaks. Plus, tips to stop them from happening again. Simple steps can save energy and headaches.

Why Refrigerant Leaks Happen in Industrial AC Units

Industrial setups are tough on equipment. Constant vibration from machinery shakes things loose. Micro cracks form in pipes. Fittings work their way free over time.

Corrosion sneaks in too. Workshop chemicals mix with humid air. Metal parts rust or pit. It’s a slow killer for seals and tubes.

Then there’s installation slip ups. Poor brazing leaves weak spots. Wrong refrigerant pressure stresses the system. Pipes rub against each other, wearing thin.

These leaks drag down performance. The unit works harder, sucking more power. Environmental harm follows, with refrigerant escaping into the air. No one wants that.

Newer energy saving air conditioner models ease the strain. They use smarter tech to balance loads. Less wear means fewer leaks down the line.

Ever notice how a small drip turns into a flood? Same here. Catching causes early pays off big.

Signs Your Workshop AC Has a Refrigerant Leak

Spotting trouble early keeps downtime low. Uneven cooling is a red flag. Some spots stay hot while others chill out.

Frost on evaporator coils? That’s classic. Low refrigerant lets ice build up. Airflow drops off.

Listen for hissing near joints. Or spot oily residue. Leaks often leave greasy marks.

Electricity bills spike without reason. The system fights to compensate. Compressor runs non stop, grinding away.

Here’s a quick checklist for techs or staff:

Check for warm air from vents.

Look at coils for frost or dirt.

Hunt for sounds or stains around connections.

Track power use against past months.

Note if the compressor cycles endlessly.

Don’t ignore these. They add up quick.

Step by Step Guide: How to Fix Refrigerant Leaks

Fixing air conditioner refrigerant leak repair starts with basics. Get it right, and the unit hums again.

a. Shut Down the System and Ensure Safety

First off, kill the power. Flip the breaker or unplug. No shortcuts here.

Grab PPE: gloves, goggles, maybe a mask. Refrigerants can irritate skin or eyes. Some types are flammable too. Better safe than sorry.

Safety isn’t just rules. It’s smart business. Exposed refrigerant might cause burns or worse in tight spaces.

b. Locate the Leak

Pinpointing saves time. Grab an electronic leak detector. It sniffs out escapes fast. UV dye works well. Add it to the system, run it, then shine a black light. Glow shows the spot. Soapy water test is old school but effective. Bubble up at suspects.

Don’t just top off refrigerant. Find the source first. Otherwise, leaks keep coming back. Tools vary by setup. In big workshops, detectors handle noise better.

c. Repair the Source

Once found, fix it. Tighten loose fittings with a wrench. Check torque specs. Re braze joints if cracked. Clean the area first. Flux helps the bond. Corroded tubing? Replace it. Cut out the bad section, solder in new. Wipe down nearby parts. Dirt invites more trouble.

Patience here. Rushed jobs fail fast.

d. Test and Recharge

Vacuum the system after repairs. Pull out air and moisture. Use a gauge manifold. Then recharge. Match the type: R22, R410A, or R32. Follow manufacturer amounts. Pressure test everything. Run the unit, watch for drops.

Get this wrong, and efficiency tanks. But done right? Smooth sailing.

How to Prevent Future Leaks & Improve Energy Efficiency

Prevention beats repair every time. Schedule checks every 6 to 12 months. Catch issues before they bite.

Clean filters and coils regular. Dirt ramps up pressure, stressing seals. Add vibration dampers under units. Insulate pipes to cut rubbing. Go for energy saving air conditioner options. They optimize compressor speed, easing load.

Monitoring tech helps too. Pressure sensors flag drops early. Leak alerts send warnings.

Each DAIHO Ventilation energy saving air conditioner is equipped with a smart control system that monitors refrigerant pressure in real time — reducing both leaks and energy waste.

Small habits add up. Like keeping doors closed to hold cool air in. Workshops stay efficient longer.

When to Call a Professional

Some fixes go beyond DIY. Large leaks need pros. Or if pressure drops repeat. Unsure on refrigerant type? Step back. Wrong mix causes damage. Certified techs know codes and tools. They handle disposal safe.

Manufacturer support shines here. OEM parts fit perfect.

Our technical support team at DAIHO Ventilation provides on site inspection and refrigerant management solutions for all our industrial air conditioner units.

Don’t risk it. Pros save money long term.

Conclusion: Keep Your Workshop Cool, Efficient, and Leak Free

Small leaks lead to big losses. Performance dips, energy wastes away. Routine checks and solid gear prevent most headaches. Invest in quality. Durable systems pay off. They run smooth with less fuss.

Looking to upgrade your current system? Explore DAIHO Ventilation’s line of industrial energy saving air conditioner units designed for 24/7 workshop performance with minimal maintenance needs.

Stay cool out there.

FAQ

Q: What causes refrigerant leaks in workshop AC units?

Vibration from machinery, corrosion from chemicals or humidity, and poor installation like loose fittings or bad brazing.

Q: How can I tell if my industrial AC has a leak?

Look for uneven cooling, frost on coils, hissing sounds, oily spots near joints, or a constant-running compressor.

Q: Can I fix a refrigerant leak myself?

Small leaks with tight fittings or simple brazing can be DIY, but always shut off power, wear PPE, and locate the leak first.

Q: How do I prevent future leaks?

Clean filters regularly, use vibration dampers, schedule check-ups every 6–12 months, and pick energy-saving units with pressure monitoring.

Q: When should I call a pro for air conditioner refrigerant leak repair?

For large leaks, repeated pressure drops, unknown refrigerant type, or if you lack proper tools and certification.