High Quality Greenhouse Cooling Pads for Better Plant Growth

-1024x683.webp)

Why Greenhouse Climate Control Starts with the Right Cooling Pads

Greenhouses trap heat. They can run 10 to 30 degrees Fahrenheit hotter than outside. This heat stress hits crops hard, cutting yields and weakening plants.

That’s where greenhouse cooling pads come in. Growers call them the core of climate control. They help improve plant health and yield by creating a balanced environment.

Many growers DAIHO Ventilation works with don’t start by asking for more fans or bigger chillers—they ask how to keep their greenhouse climate stable enough for consistent yields.

How Evaporative Cooling Pads Shape Greenhouse Temperature and Humidity

Evaporative cooling pads for greenhouses work through a simple process. Water circulates over the pads. Hot air passes through the wet material. Evaporation pulls away heat. Cooler, moister air flows into the greenhouse. This can drop temperatures by 10 to 20 degrees Fahrenheit.

Quality pads get incoming air closer to the wet bulb temperature. That means more even cooling across the space. In a fan and pad greenhouse cooling system, this setup handles temperature and humidity control like a pro.

From Microclimate to Yield: Why Stable Conditions Matter to Plants

Plant health and yield in greenhouses depend on steady temps. Tomatoes thrive at 70 to 85 degrees Fahrenheit during the day. Leafy greens prefer 60 to 75. Cucumbers like it around 75 to 85. Flowers vary, but most hate swings above 90.

High heat causes trouble. Flowers drop. Fruits don’t set. Sugars build up wrong. Pests and diseases jump in.

The Microclimate Factor

Think about canopy height. Tops of plants can run hotter than lower leaves. This messes with transpiration. Leaves sweat unevenly. Growth stalls.

Prevent heat stress in greenhouse crops with solid control. Optimal temperature for greenhouse plants keeps everything humming. Yields climb when conditions stay right.

Sometimes, a small temp dip at night helps too. But daytime spikes? They ruin batches.

What Makes a High-Quality Cooling Pad – and Why It Shows Up in Your Crops

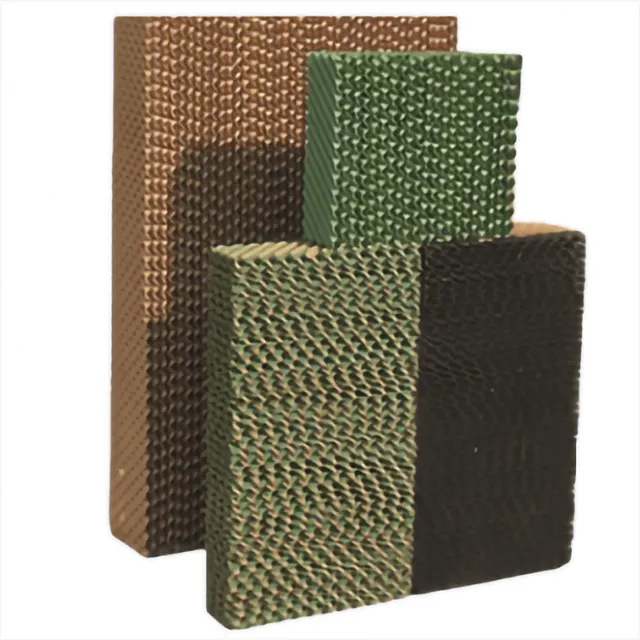

High-quality cooling pads stand out in key ways. Material matters first. Cellulose greenhouse cooling pad types use strong fibers. Wavy structures and right thickness let air flow smooth.

Density plays a role. Thicker, denser pads hold more water.

Key Features of Top Pads

Saturation Efficiency: Aim for 85 to 90 percent. Low-end pads hit 60 percent, meaning weaker cooling. This shows in pad efficiency metrics.

Airflow Uniformity: Even wetting avoids cold spots and hot zones. Crops get balanced air.

Durability: They resist water damage, UV rays, and crumbling. Expect 5 to 7 years of service.

These traits link straight to crops. Efficient pads mean stable climate. That extends seasons. Yields become predictable. Plants stay healthier.

For example, DAIHO Ventilation designs its black cellulose pads with higher density and strong bonding to keep saturation efficiency in the 85–90% range, which growers notice as more even temperatures along the crop rows.

Ever notice how some pads flake after a season? That’s low quality hurting your bottom line.

How Better Cooling Pads Change Greenhouse Outcomes

Greenhouse cooling pad case study stories show real gains. Take a tomato setup. Before, summer peaks hit 100 degrees Fahrenheit. Fruits cracked. Flowers fell off.

After swapping to high-quality pads, max temps dropped to 86 degrees. Cracking cut way down. Flowers stuck around. Yields jumped 15 percent.

One grower switching to DAIHO Ventilation pads reported that peak summer canopy temperatures dropped by 3–4°C, enough to keep their tomato flowers from aborting during heat waves.

Improve tomato yield with cooling pads? Absolutely. Better seedling quality with stable climate follows suit. These shifts add up fast.

Integrating High-Quality Cooling Pads with Fans and Ventilation

A fan and pad greenhouse cooling system needs smart setup. Place pads opposite exhaust fans. This creates a flow: pad to crops to fans.

Aim for air changes every 1 to 2 minutes. That keeps fresh air moving.

Adjusting for Climate

In dry, hot areas, pads shine. They add needed humidity.

Humid spots? Vent more. Open sides if possible.

Greenhouse ventilation with cooling pads boosts airflow design for greenhouse climate control. Fans pull, pads cool. Simple. But watch pad size. Too small, and fans work overtime. Balance is key.

Maintenance and Water Quality: Keeping Your Pads Performing Like New

Water quality for evaporative cooling pads affects everything. Hard water builds scale. Iron stains and clogs. Air passages block up.

This drops efficiency. Pads wear out quicker.

Tips for Longevity

Flush pads regularly. Check for dry spots.

Filter water based on quality. Soften if needed.

Block algae and biofilms. Clean systems prevent growth.

Cooling pad maintenance for greenhouses keeps them fresh. Extend cooling pad service life with these steps. Neglect it, and yields suffer.

Sometimes, a quick hose-down mid-season saves headaches.

Simple Checklist: Are Your Cooling Pads Helping or Hurting Your Plants?

Greenhouse cooling pad checklist helps spot issues. Run through these:

Is incoming air cool and even across the greenhouse?

Any obvious dry patches or water channels on pad surfaces?

Temp difference front to back within 5 degrees?

Pads crumbling or smelling after a few years?

Humidity levels steady, not spiking?

Crops showing heat stress signs like wilted leaves?

Airflow strong without dead zones?

Water system free of clogs or leaks?

Pads saturating fully during operation?

Overall yields consistent season to season?

Signs your cooling pads need replacement? If half these fail, upgrade. High-quality ones fix most.

Conclusion: Investing in Climate Stability, Not Just Hardware

Stable climate drives high yields. Greenhouse cooling pads anchor that stability. They cut heat, balance humidity, and even out air.

Crops respond. Healthier plants. Bigger harvests. Fewer surprises.

Greenhouse climate control for better yields starts here. Quality pads pay off in the long run. They turn hardware into results.

FAQ

Q: How do cooling pads help control temperature in a greenhouse?

Cooling pads use evaporative cooling: warm air passes through wet cellulose pads, loses heat through evaporation, and enters the greenhouse as cooler, more humid air—reducing temperatures by 5–15°C depending on climate.

Q: What makes a high-quality greenhouse cooling pad different from a low-cost one?

High-quality pads have better cellulose density, stronger bonding, higher saturation efficiency (often 85–90%), and longer lifespan. They deliver more uniform cooling and maintain performance for several seasons.

Q: Can cooling pads improve plant health and yield?

Yes. By reducing heat stress and stabilizing microclimate conditions, cooling pads help maintain photosynthesis, reduce flower/pod drop, and support stronger growth—leading to more consistent and higher yields.

Q: Do cooling pads work in humid climates?

Cooling pads work best in dry to moderately humid conditions. In regions where humidity exceeds 70%, the cooling effect decreases, but airflow and slight temperature reduction can still help reduce crop stress.

Q: How often should greenhouse cooling pads be maintained or cleaned?

Most growers rinse pads every few weeks during peak season and perform deeper cleaning once or twice per year. Good water quality and regular flushing prevent scaling, algae, and clogged airflow.