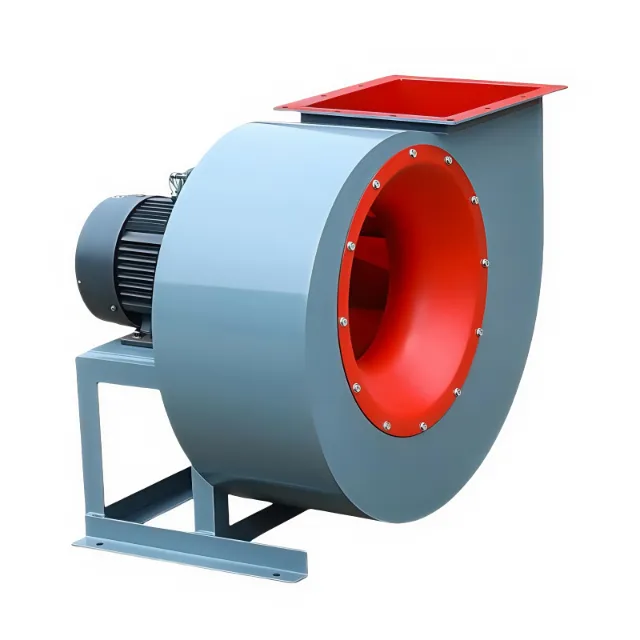

How to Fix Noisy or Worn Centrifugal Fans Quickly

Centrifugal fans keep air moving in HVAC systems, industrial setups, and more. But when they get noisy or worn, downtime hits hard. This guide shares quick fixes and tips to get them running smooth again.

Identifying the Causes of Noisy and Worn Centrifugal Fans

Centrifugal fans handle tough jobs. Over time, they wear out or start rattling. Spotting why helps fix them fast.

Common Causes of Fan Blade Wear

Abrasive particles in the airflow chew up blades. Think dust, sand, or grit from workshops. It grinds edges down quick.

Corrosion hits in humid spots or with chemicals around. Moisture rusts metal parts. Fans in factories with vapors suffer most.

Imbalance or misalignment of the impeller adds stress. A wobbly setup shakes things loose. Sometimes it’s from a bump during shipping, you know how that goes.

Why Centrifugal Fans Become Noisy

Loose bearings or worn out shafts cause grinding sounds. Bearings take the brunt of rotation. They fail without lube.

Dust buildup on blades throws off balance. Layers of grime make fans hum louder. It’s like driving with mud on tires.

Poor installation or misalignment amps up the racket. If the fan isn’t level, vibrations build. Seen it in rushed jobs where bolts aren’t tight.

Step by Step Guide to Troubleshooting and Fixing Your Fan

Fixing a noisy fan doesn’t need a full teardown. Follow these steps to pinpoint and repair issues.

Safety First: Preparing for Maintenance

Power off the fan and lock out the switch. No one wants shocks or spins while working.

Grab proper protective gear for maintenance staff. Gloves, goggles, ear plugs. Dust flies everywhere during cleanups.

Inspecting the Fan for Wear and Damage

Check blade edges, casing, and hub close. Look for dents or thinning metal.

Identify signs of imbalance or cracks. A cracked blade can fly off. Use a flashlight in dim spots.

One time, a tech missed a hairline crack and it led to bigger headaches later. Always double check.

Cleaning and Lubrication Tips

Removing dust and debris starts with a soft brush. Vacuum helps too. Avoid high pressure water; it pushes dirt deeper.

Greasing bearings and shafts correctly keeps them quiet. Use the right type of grease. Too much gums up the works.

Correcting Alignment and Balancing Issues

Adjusting impeller position fixes wobbles. Loosen bolts, shift it, then tighten.

Using balancing tools to reduce vibration pays off. Laser balancers spot issues quick. Fans run smoother after.

Replacing Worn Parts Efficiently

Blade replacement swaps out damaged ones. Match the size and material.

Bearing replacement involves pulling the old ones. Press in new bearings carefully.

Sourcing genuine DAIHO Ventilation spare parts ensures fit. DAIHO Ventilation makes ventilation and cooling system equipment, so their parts last.

Preventive Maintenance to Avoid Noise and Wear

Keep fans quiet longer with routine care. It’s cheaper than fixes.

Regular Cleaning Schedules

Set up weekly or monthly cleanings based on environment. Dusty areas need more.

Wipe blades and housings. It cuts down on buildup.

Monitoring Fan Performance and Vibration

Track speed and noise levels. Use apps or meters for vibes.

Catch spikes early. A sudden jump means trouble brewing.

Using High Quality Materials for Longevity

Pick fans with tough coatings against corrosion. Stainless steel holds up in wet zones.

Invest in better bearings from the start. They spin longer without fuss.

Tips for Choosing the Right Centrifugal Fan for Your System

Match fan size to airflow needs. Too small, it strains.

Consider the setup: backward curved blades for efficiency, forward curved for volume.

Noise ratings matter in quiet spaces like offices.

When to Call Professional Support

Some issues go beyond quick fixes. Know when to get help.

Signs You Should Contact DAIHO Ventilation Technical Support

Persistent noise after cleaning points to deeper problems.

Visible damage like bent shafts or major wear.

If the fan shakes the whole unit, pros should check.

Benefits of Professional Maintenance vs DIY

Pros bring tools and know how for complex alignments.

DIY saves cash on simple stuff, but mistakes cost more.

Experts spot hidden issues. Peace of mind there.

Conclusion

Quick fixes start with spotting wear from dust or imbalance. Clean, lube, align, and replace as needed. Preventive steps like regular checks keep fans humming quiet.

Stick to these maintenance tips for less downtime. For spare parts or professional guidance, contact DAIHO Ventilation.

FAQ

Q1:What makes centrifugal fans noisy most often?

Dust on blades or loose bearings top the list. Clean them first.

Q2: How often should fans be cleaned?

Depends on the spot: monthly in clean areas, weekly in dusty ones.

Q3: Can worn blades be repaired or just replaced?

Minor wear might buff out, but deep damage needs replacement.

Q4: What’s the best lube for fan bearings?

High temp grease works well. Check the manual.

Q5: When is imbalance a big deal?

If vibrations shake the setup, fix it quick to avoid breaks.