Why Factories in Southeast Asia Struggle with Heat and Humidity Control?

Factories in Southeast Asia face a daily fight against hot and sticky air. Warmth gathers inside big workshops. Moisture sticks to machines, walls, and products ready for packing. Over time, this makes workers tired. It lowers their work speed and harms costly equipment. Many bosses know better airflow is needed. Yet, they wait until issues grow serious. This leads to high repair costs.

One company helping factories is Daiho. They focus on ventilation systems for years. Their equipment handles hot temperatures, wet air, and rough outdoor weather in tropical places. What sets them apart is not only their machines. They also ensure long lasting performance. From custom designs to maintenance tips, Daiho values reliability. Their about us page shows trust built with textile plants, poultry farms, and warehouses. Check their service section for hands on support that keeps machines working well. Their contact team answers questions fast. In short, Daiho is a go to choice for businesses fed up with heat issues.

What Makes Southeast Asian Factories So Hot?

Step into a textile shop or shoe factory in Jakarta or Ho Chi Minh City. You feel heavy, warm air right away. Machines run all day, creating heat that stays trapped. Metal roofs make buildings feel like hot ovens by noon. With humidity at 70–90 percent, the air feels thick and tough to bear. Small ventilation gaps don’t help much. Old style ceiling fans just move warm air around in circles.

Why Do Conventional Fans Fall Short?

Regular fans often lack power to push out big amounts of air from closed workshops. They work okay in small spaces. But in large halls with many workers, they barely help. Many use belt drives, which make loud noise and wear out quickly. Rain and dust sneak in through weak covers. This makes fans rust after just one rainy season. You end up buying new ones before they save you money.

How Does Humidity Damage Equipment and Products?

Humidity isn’t just about feeling uncomfortable. It creeps into electronics and weakens wire insulation. It also rusts steel parts. Food factories deal with mold growth. Printing shops see paper curl and colors fade. Textile fibers soak up moisture, making them tricky to work with. These quiet losses don’t always show in reports. But over a year, they add up to big costs.

Can Ventilation Reduce Moisture Problems?

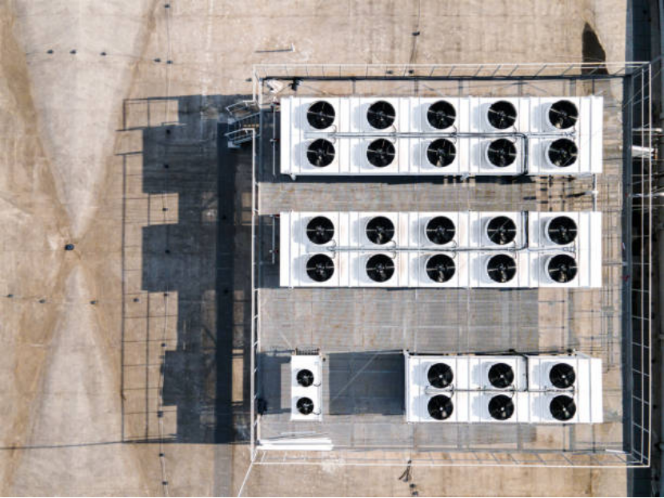

Yes, good ventilation cuts down indoor dampness. It moves wet air out and brings in fresh air. The right system stops water drops from forming on walls. It also keeps temperatures steadier. Modern tools, like the Industrial Rooftop Mounted Exhaust Fan Slope Type, have waterproof domes and wind deflectors. These pull large amounts of air upward. They shield insides from heat and moisture. Unlike flat covers, the sloped cap pushes rainwater away. This stops leaks during tropical storms.

Why Do Workers Suffer in Poorly Ventilated Workshops?

Bad airflow takes a toll on workers. It makes them tired and slow. Safety studies show a 2°C jump in room temperature cuts work output by 5–7 percent. In dyeing or laundry shops, heat can harm health. Workers take longer breaks or miss work more often. They also make more mistakes when they can’t focus due to hot air.

What Role Does Noise Play in Comfort?

Noise often gets overlooked in ventilation talks. Many exhaust systems sound like loud engines. This forces bosses to pick between fresh air and bearable noise. Direct drive fans fix this. They cut out belts and extra parts. Less shaking means quieter, smoother running. In places like net cafés, supermarkets, or waiting areas, this keeps customers happy and workers calm.

How Do Farms and Greenhouses Handle Ventilation Challenges?

Farms don’t use heavy machines like factories. But they have their own airflow problems. In poultry sheds, birds pack close and give off heat and dampness. Without good airflow, ammonia builds up. This stresses animals and raises disease risks. Greenhouses face high moisture too. It leads to fungus that harms crops.

Which Fans Work Best in Agricultural Settings?

For farms, airflow must be steady and cover wide areas. Roof mounted fans push out heat and smells before they settle. Models like the Elbow Type fit open sheds. They send air sideways, not straight up. This blocks rain from getting in, even in stormy areas. For big poultry farms, direct drive systems save energy and are easy to clean. Farmers like this during routine checks.

What Are the Long Term Benefits of Strong Ventilation?

Good ventilation isn’t just about feeling cool now. It brings lasting perks. It cuts down on machine breakdowns. It improves product quality. It also lowers health issues among workers. In warehouses, steady airflow protects stored goods from dampness. In rubber or plastic molding shops, it keeps curing processes stable. With free moving air, energy bills drop. You rely less on extra cooling tools like portable fans or air conditioners.

How Does Structure Strength Affect Lifespan?

Roof fans face tough sun, rain, and wind. That’s why strong housings, often made of fiberglass reinforced plastic, are favored. They resist rust and survive storms. They last longer than metal frames. SMC glass fiber blades are light but sturdy. They hold their shape after years of spinning.

FAQ

Q1: What is the main cause of heat build up in Southeast Asian factories?

High outdoor heat, metal roofs, and machine warmth trap hot air inside. This is worse in big workshops.

Q2: How does humidity affect industrial products?

It harms electronics, rusts steel, spoils food, and warps paper and textile fibers.

Q3: What type of exhaust fan is best for rainy climates?

Roof mounted fans with sloped waterproof caps and wind deflectors work best. They block rain while keeping strong airflow.

Q4: Why do farms need strong ventilation?

Farms have heat, odor, and moisture from animals. Good airflow lowers animal stress, cuts disease risks, and helps crops grow healthy in greenhouses.

Q5: How does strong ventilation save money over time?

It stops product spoilage, extends machine life, lowers energy costs, and reduces worker sick days due to heat or bad air.