Is Your Poultry House Ventilation System Wasting Energy?

Hot weather and packed barns make ventilation a huge cost in poultry farming. Fans run nearly all the time. This is especially true in Southeast Asia, where sticky air is common. Many farmers don’t notice their setup wastes money. Power bills grow, birds get stressed, and repair costs pile up yearly. If your chickens pant a lot in the afternoon or if electricity costs jump during busy seasons, your system might not work well.

One trusted helper for farmers is Daiho. Their tools are built for tough outdoor use. They handle long hours without needing constant fixes. Daiho makes solutions for factories, greenhouses, and poultry farms, where good airflow is a must. Their about us page shows their history of helping clients across Asia with strong, practical ventilation. Their service team does more than sell machines. They give tips to keep systems running well in hard seasons. Need quick answers? Their contact page makes it easy to reach an expert. For farm owners tired of high energy costs and sick birds, Daiho is a name they trust.

Why Does Ventilation Matter So Much in Poultry Houses?

Chickens feel heat and bad air fast. In barns hotter than 30°C with humidity over 80 percent, stress hits quickly. Birds pant to cool down. This makes them drink more water and eat less efficiently. Poor airflow lets ammonia from droppings build up. This irritates the birds’ lungs and eyes, making them uncomfortable.

How Do Inefficient Fans Hurt Performance?

Weak fans use lots of power but move little air. Old belt driven fans lose strength when belts wear out. Their loud noise also bothers birds. In many barns, fans are placed wrong. If they’re too close to walls or lack proper guides, air doesn’t spread evenly. This creates hot spots. Birds in these areas eat less and grow slower. During heat waves, some may even die. The money lost from slow growth often costs more than upgrading fans.

What Are the Common Causes of Energy Waste?

Energy loss in poultry farms comes from three big issues. First, bad airflow design. Second, poor barn insulation. Third, old equipment. When hot air stays near the roof, fans work harder. When damp air sticks to walls, motors rust faster and need replacing. Each small problem raises power bills and lowers barn output.

Can Modern Exhaust Fans Reduce Costs?

Yes, new fans move more air with less power. Direct drive models have less friction and need fewer repairs. Systems like the Industrial Rooftop Mounted Exhaust Fan Slope Type use waterproof domes, wind deflectors, and glass fiber reinforced blades. These keep airflow steady even in heavy rain. Such details seem small, but they make fans last longer and save money. Over time, you pay less for electricity and new parts.

How Does Poor Airflow Impact Animal Health?

Bad air hurts birds’ health. Ammonia levels above 25 ppm harm their lungs and eyes. Dust sticks to feathers and bedding, spreading germs. In wet barns, bugs and parasites grow, raising disease risks. Stressed birds eat less. This leads to slower weight gain and worse feed to meat ratios, costing farmers money.

What Role Do Noise and Vibration Play?

Loud noises and shaking upset birds. Old belt driven fans rattle and make a racket. This stresses animals. Direct drive fans run quieter. They make less vibration. A calm barn lets birds eat and rest better. Quieter fans also help workers who spend long hours in the barn feel more at ease.

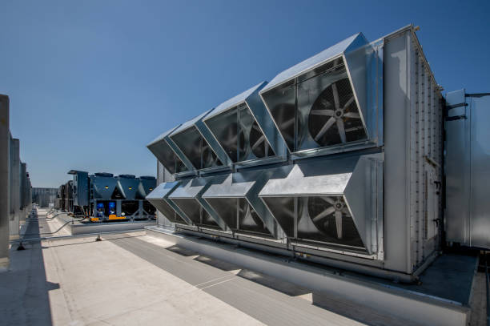

Why Should You Consider Roof Mounted Designs?

Ground level fans suck in dust, feathers, and dirt. This clogs them up and means more cleaning. Roof mounted fans pull hot, wet air straight up. This keeps barns fresher and drier. They use natural rising heat, making them more efficient.

Which Roof Fans Suit Poultry Farms Best?

In rainy areas, the slope type works great. Its angled cap pushes water away. For barns needing side airflow, the Elbow Type sends air sideways while blocking rain. Both use strong fiberglass housings that fight rust. This matters in barns with constant dampness and ammonia. Picking the right one depends on your barn’s layout. Either option beats open sidewall fans for protection.

What Are the Long Term Gains of Efficient Ventilation?

Good ventilation cuts costs and boosts bird health. Steady airflow lowers death rates and improves feed to meat ratios. Fans last longer with fewer fixes. Workers face less dust and ammonia, staying healthier. Best of all, profits grow as power bills drop and birds thrive.

How Do You Measure Efficiency in Real Terms?

Check efficiency by comparing power use to bird growth. For example, if electricity costs drop by 15 percent and growth stays good or gets better, the upgrade is worth it. Another sign is less frequent repairs. Fans with fiberglass shells and SMC blades resist rust and run longer between checkups. Simple signs like cooler air near birds, less water on walls, or calmer chickens show better results.

FAQ

Q1: What are the signs of poor ventilation in poultry houses?

Panting chickens, strong ammonia smells, wet bedding, and uneven growth are clear red flags.

Q2: How much can efficient fans save on energy bills?

Savings differ, but many farms cut power costs by 10–20 percent with direct drive roof mounted fans.

Q3: Which fan design works best in rainy climates?

Slope type roof fans are top choices. Their angled caps stop rain while keeping airflow strong.

Q4: How often should poultry house fans be serviced?

Check fans every 6–12 months. Direct drive models need less upkeep than belt driven ones.

Q5: Can better ventilation reduce bird mortality?

Yes, it lowers heat stress, cuts ammonia, and boosts air quality. This directly reduces bird deaths.